BARRICADE® Insulated Subfloor

CLOSED CELL XPS FOAM

R-VALUE OF 3.2

3,153 LBS/SQ FT COMPRESSION STRENGTH

23.25” X 23.25” X 1”

Panel Overview

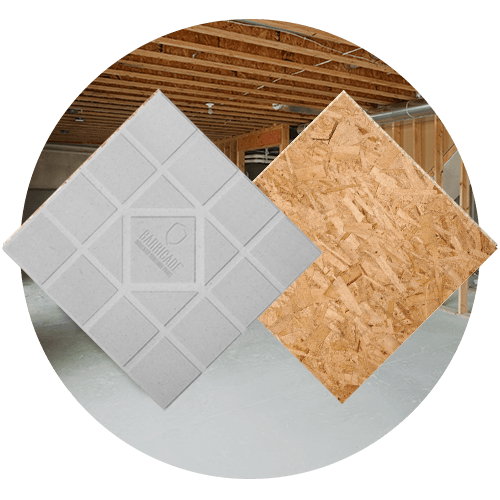

Barricade® Insulated Subfloor

Barricade® Insulated panel aims to provide the highest levels of warmth and comfort. With an R-value of 2.7, Barricade® Insulated panel provides twice the insulating strength as Barricade® Air Plus.

- Strong enough to support up to 3,153 lbs/sq.ft. (1,430 kg/sq. ft.)

- Helps promote healthy indoor air quality

- Protects any finished floor type

- Tongue and groove design makes installation fast and easy

- Limited 25 year warranty

CAPILLARY BREAK

Creates healthier air quality by helping protect against moisture, mold, mildew and small water leaks

WARMTH

Increases floor temperatures by up to 10° C / 19° F (R-Value 2.7)

COMFORT

Softens finished floors against hard concrete

23.25” X 23.25” X 1”

59 cm x 59 cm x 2.5 cm

Barricade® Video

Installation Steps

Installing the right foundation

1. Preparation

The concrete floor and foundation should be relatively dry and free of large cracks, excessive moisture penetration or flooding problems prior to installing Barricade® Insulated Subfloor panels.

2. Subfloor panel preparations

Make as much space as you can spare in the area where you will be laying the Barricade® panels. Remember, you'll need space to stack the panels, which should be away from where you begin laying the floor. Also, allow panels to acclimate to the basement environment for approximately 24hrs prior to installation.

3. Installation tools needed

- Hammer

- Tapping block (piece of 2″x4″ lumber)

- Saw

- Pencil

- Level

- ¼” / 0.6 cm spacer (example: wood strip)

- Tape measure

- Pry bar or crowbar (optional)

- Barricade® Leveling Shims

Comparison Table

See the differences between Barricade® Air Plus vs Barricade® Insulated Subfloor panels

| Product |   |   |   |

|---|---|---|---|

| R-Value | 1.4 | 2.7 | 4.1 |

| Compression Strength (lbs. / sq. ft.) | 6,642 lbs. (3,012 kg) | 3,153 lbs. (1,430 kg) | 3,650 lbs. (1,659 kg) |

| Top | OSB | OSB | EPS Foam |

| Bottom | High Density Plastic | Foam | EPS Foam |

| Weight | 6.6 lbs. (3.0 kg) | 6.1 lbs. (2.7 kg) | 1.6 lbs. (0.7 kg) |

| Height | 0.75" (1.9 cm) | 1" (2.5 cm) | 1" (2.5 cm) |

| Size | 23.25” x 23.25” x 0.75" (59 cm x 59 cm x 1.9 cm) | 23.25” x 23.25” x 1" (59 cm x 59 cm x 2.5 cm) | 47.25” x 23.25” x 1" (120 cm x 59 cm x 2.5 cm) |

| Finished Flooring Options | For laminate, hardwood, carpet, vinyl, tile, stone plastic composite | For laminate, hardwood, carpet, vinyl, tile, stone plastic composite | For hardwood, laminate, >5mm luxury-vinyl (LVT/LVP), stone plastic composite |

| Warranty | 25 Year | 25 Year | 25 Year |

*Based on modified ATSM C518-17 testing using LVT >5mm

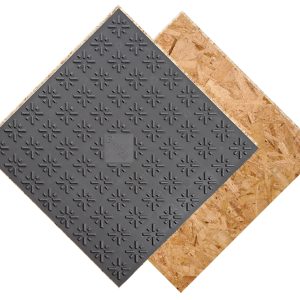

BARRICADE™ Air Plus Panel

- R-Value 1.4

- *Floor temperatures +7° C / +14 ° F

- Compression strength 6,642 lbs. per sq. ft

- OSB (top)

- High Density Plastic (bottom)

- 6.6 Lbs

- 3/4" Height

- 23.25" x 23.25" Dimension

- 25 Year Warranty

- For vinyl (LVT/LVP), laminate, engineered hardwood, carpet, tile

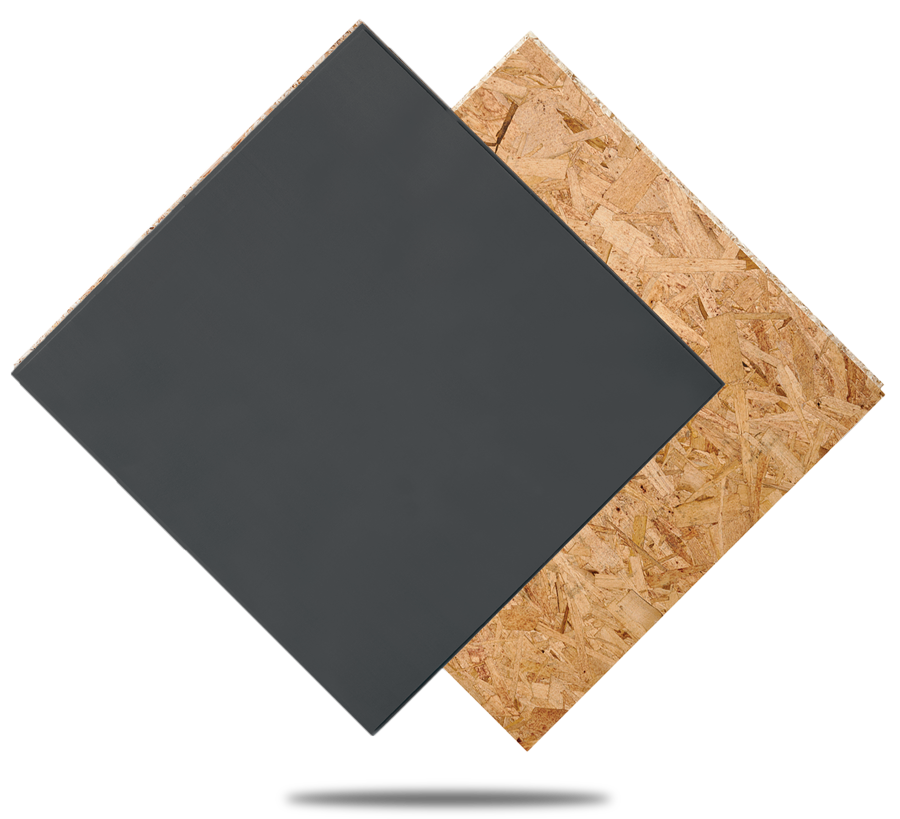

BARRICADE™ Insulated Panel

- R-Value 3.2

- *Floor temperatures +10° C / +19 ° F

- Compression strength 3,153 lbs. per sq. ft

- OSB (top)

- XPS Foam (bottom)

- 6.0 Lbs

- 1" Height

- 23.25" x 23.25" Dimension

- 25 Year Warranty

- For vinyl (LVT/LVP), laminate, engineered hardwood, carpet, tile