BARRICADE™ CONCRETE REPAIR

Engineered to seal, fill and structurally reinforce concrete.

YOUR DEFENSE AGAINST COLD, HARD CONCRETE FLOORS

Contractor Rewards

Are You

a contractor?

If you’re a Contractor who purchases Barricade Subfloors, you have the opportunities to earn a FREE $25 gift card for every 100 panels purchased from your preferred home improvement retailer.

Why You Need Subfloors!

Moisture Protection

Insulation

Concrete floors are cold to walk on. Our Subfloor systems provides a thermal break between the cold concrete and your finished floors, which can raise your finished floors’ temperature by up to 10°C or 19°F, making your basement floor feel as warm as any other room in your house.

Comfort

Concrete floors are unforgiving and can be hard on your joints over time. A subfloor system helps soften your finished floors against hard concrete, making it more comfortable to walk on.

WHY BARRICADE®?

The first step to a warm, comfortable basement floor is to use a subfloor system. BARRICADE® Subfloors are specifically designed to be installed on top of concrete floors, making your basement feel as comfortable as any other room in your home. All BARRICADE subfloors provide:

- A capillary break to help protect against moisture, mold and mildew and small water leaks

- A thermal break to help insulate against the cold concrete

- A solid structure that is more than strong enough to support the heaviest home furnishings

Basement Science Behind BARRICADE®?

BARRICADE® SUBFLOOR AIR PLUS

The first and most important step to creating a warm and comfortable basement environment just like any other room in your home.

There’s no easier way to increase living space in your current home than by developing your basement, and starting with the right foundation is essential to a successful basement project.

AIR FLOW

Creating positive air flow to allow moisture to evaporate naturally, to help protect against moisture, mold, and mildew

WARMTH

BARRICADE® Air Plus has an R-Value of 1.4 to help make floors up to 7° C / 14° F warmer.

EASY INSTALLATION

BARRICADE® Subfloors are quick and easy to install. A standard 500 sq. ft. room (46 m2) can be completed in an afternoon

SOFTENS FLOORS

Eases strain and impact from walking on hard concrete

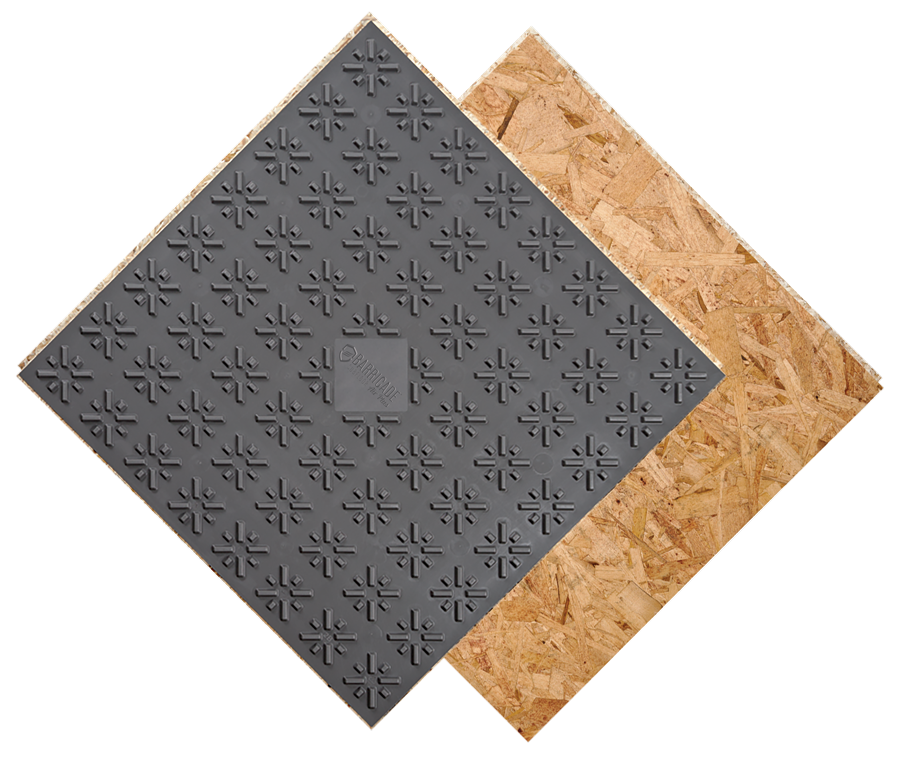

BARRICADE® INSULATED SUBFLOOR

For even more insulation for more warmth and comfort!

CAPILLARY BREAK

Creates healthier air quality by helping protect against moisture, mold, mildew and small water leaks

WARMTH

BARRICADE® Insulated has an R-Value of 2.7 to help make your floors up to 10° C / 19° F warmer.

EASY INSTALLATION

BARRICADE® Subfloors are quick and easy to install. A standard 500sq. ft. room (46 m2 ) can be completed in an afternoon

SOFTENS FLOORS

Eases strain and impact from walking on hard concrete

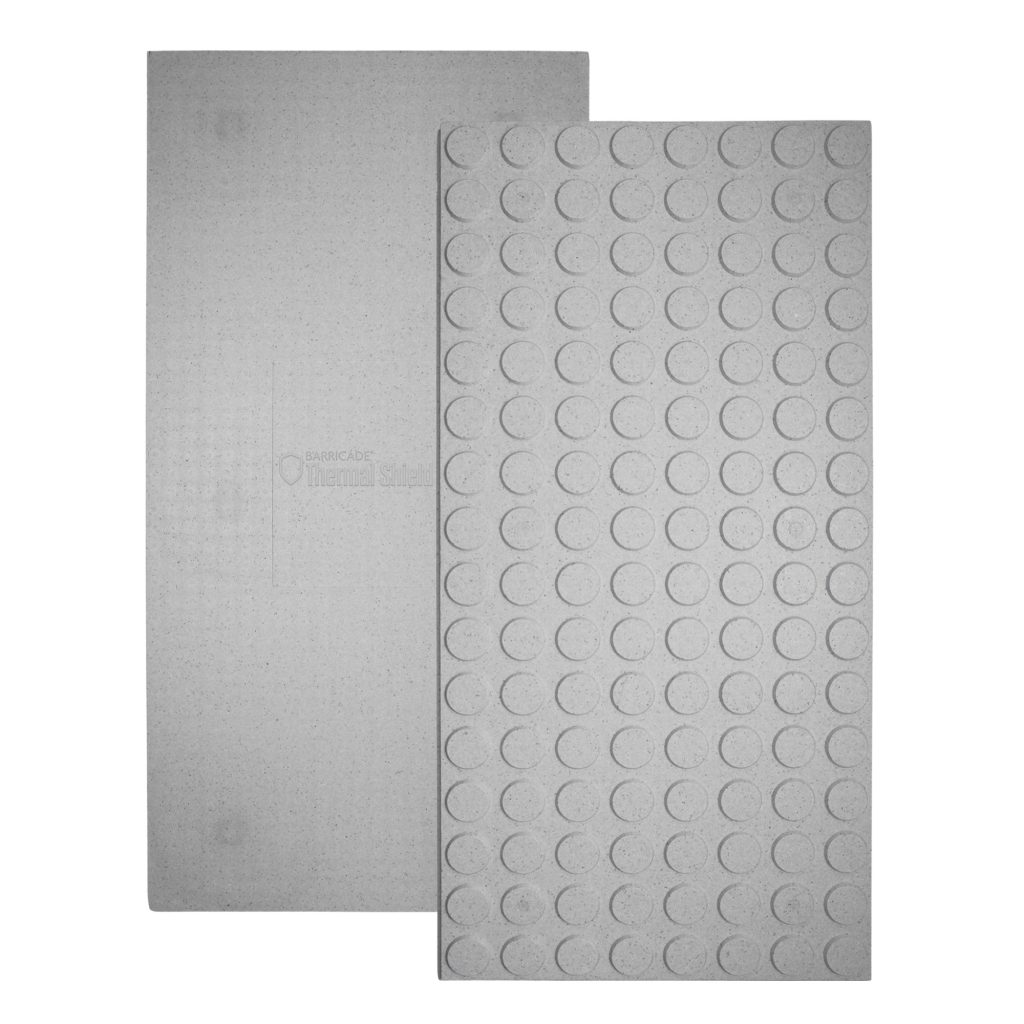

BARRICADE®

Thermal Shield

For the most warmth in Barricade’s lineup and even easier to install!

AIR FLOW

Creating positive air flow to allow moisture to evaporate naturally, to help protect against moisture, mold, and mildew

WARMTH

BARRICADE® Thermal Shield has the highest R-Value in the lineup at R-4.1

EASY INSTALLATION

No power tools required and can be cut with a utility knife

SOFTENS FLOORS

Eases strain and impact from walking on hard concrete